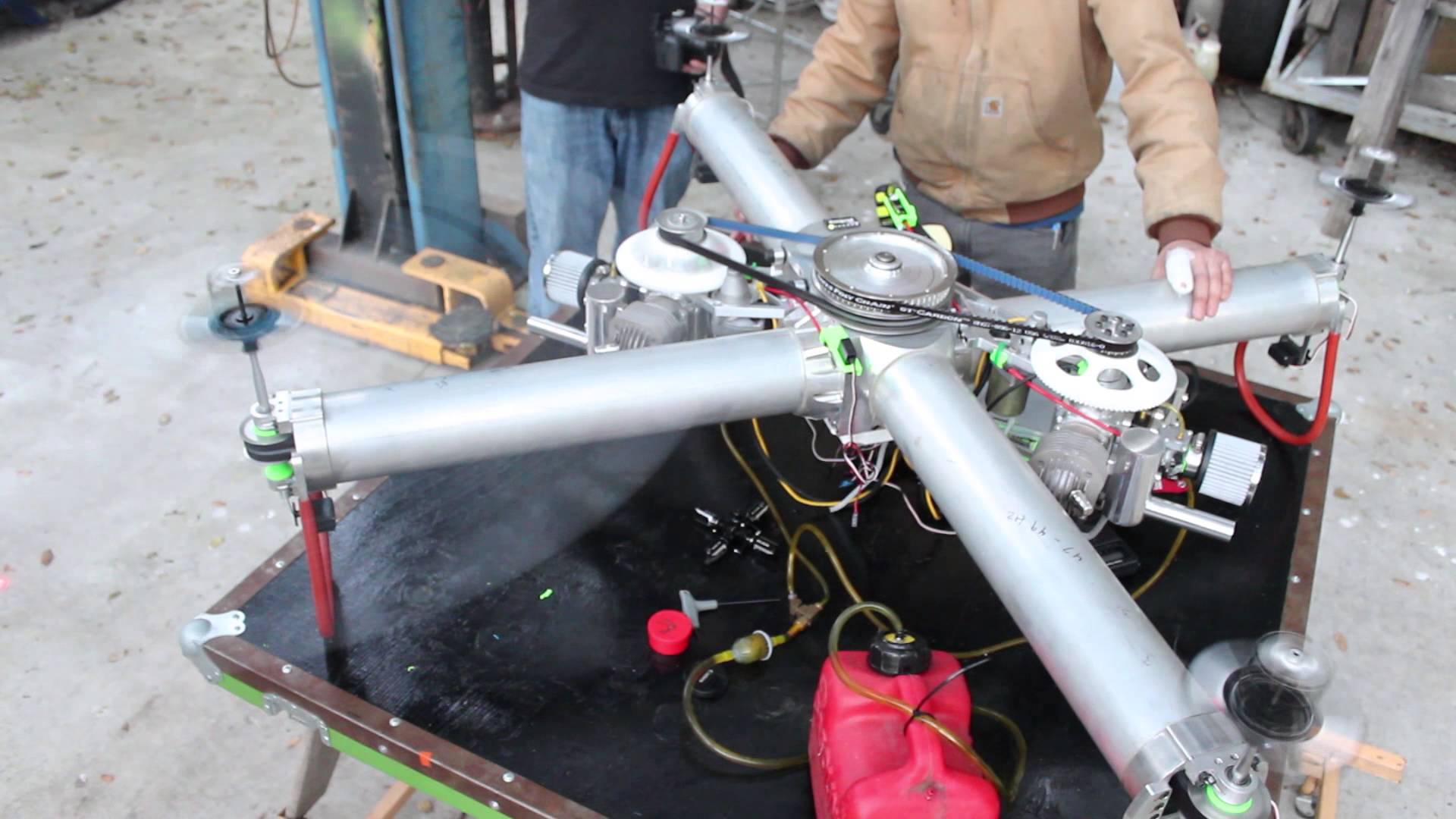

The ad hoc blade lock solution tested successfully as seen in this video. It will provide the protection needed for the blades to continue with our testing sequence towards first flight. We also took advantage of this time to determine what the lower engine speed limit is to help in the programming of the engine controller.

Nice… Keep on posting… Can it lift 25kg?

good luck guys, im following this project

What happened the guy’s finger?

this quad is incredible!! Such a nice project:) good luck, please do more videos!

I am also following your project. I am assuming that you’ d be keeping the engine RPM constant and changing the blade angles with swashplates and servos that can be clearly seen in the videos to control the quad. That means you can also fly it inverted just like my RC Helicopters. Nice.

Please keep posting.

Very interesting project. One question; when it’s all done, will you release the engine and pitch controller under GPL? Currently the hobby community lacks a good open source flight controller with support for variable pitch quadcopters. I’m pretty sure the MultiWii or Cleanflight guys wouldn’t mind 🙂

How do you have such professional quality videos as a student project :)?

I suppose you expect either the army or matternet/ray Kurzweil will be knocking on your door pretty soon… and line your pockets with gold.

interesting…. good luck

What is the expected thrust? Very nice project guys, good lucky.

When will it fly

what about manual control of engine RPM from the transmitter and use a traditional flight controller to control pitch instead of throttle.

hope this one fly!!! waiting to see~!!

hey guys! why not use a differential with a brake at one end and a propeller at the other to adjust the speed according to the friction applied by the brake

Could you use heat shrink for the Ad hoc solution? I suppose you will want to disassemble it sometime so probably not. Just a thought.

Dont you think each of the four main rotor shafts should have a one way bearing clutch fitted? In the event your engine cuts out, this will allow auto-rotation like a helicopter. Its also a lot less stressful on the blades if the engine stops suddenly. Seems like you have more engine power than blade area to me, make those booms / blades longer, or are you restricted to the length of those endless drive belts?

i agree with +DerKrawallkeks do more videos!

keep it coming….wishing all the success for your project!

When are you guys going to post more videos of this monster. So curious to see in in the air 🙂

Have you guys gotten this to fly yet?

Just a question, how will you guys achieve yaw control with constant rpm. Ok I know you will get some torque difference just from pitch change, but will it be enough?

what flight control do u use on this quadcopter?

ohh this is going to be the best quad imagine how much this thing is going to be able to lift? can’t wait to see it fly

Great Idea ! Maybe you guys should try tuned muffler with the engines .

The standard muffler come alone with those engines are just use to reduce noise . Good luck .

Congrat for the project! When can i see it flying?

need to test the full range of motor. these 2 stroke motors? it seems to me the test stopped at 50% throttle.? 3d printed parts + high stress/vibration= failure? just my thoughts/ trying to help cause i love what you guys are doing/accomplishing!

You nick you finger?

great project! but why the music? it destroys any chances of hearing anything of what is happening. gearheads like me want the sound! please ditch the music.

COOL! Sharp build!

Are u going to make a new video

Great project but I cant understand why you risk everything with home made props when every size and pitch can be bought so easily.

Tested for a yr ago and not flying yet?

junk can’t fly

We don’t need shit background music

0016X0116X2128X67054

Well, I suppose it never flew…..no more vids.